Latest from the Academy

New £150 million Green Future Fellowships programme to research breakthrough technologies and solutions for net zero

Major new funding available for researchers developing scalable technologies to help the UK and the world reach net zero and adapt to climate change

Engineering artworks on show at Innovation Late event at Edinburgh Science Festival

Unique photographs depicting Scottish engineering innovations to be shown for the first time

Academy announces seven new Policy Fellows

Latest successful applicants join the Policy Fellowships programme in its fifth year.

New Fellows 2023

The Fellowship of the Academy is an unrivalled community of leading business people, entrepreneurs, innovators and academics from every part of engineering and technology, who shape the Academy's work to build a sustainable society and inclusive economy that work for everyone.

Professor David Phoenix OBE DL FREng

Professor David Phoenix’s bio-molecular engineering research on soft matter and its interface with medical devices is advancing drug design and improving thousands of people’s lives through new pulmonary treatments.

Read moreDr Marlene Kanga AO FREng

Dr Marlene Kanga, an Officer of the Order of Australia for distinguished service to engineering, is an inspiring leader, listed among Australia’s top women engineers. She was the National President of Engineers Australia (2013) and President of the World Federation of Engineering Organizations (2017-2019).

Read moreDr Sabesan Sithamparanathan FREng

Dr Sabesan Sithamparanathan is a multi-award-winning academic entrepreneur who invented and developed the world’s most accurate battery-free radio frequency identification tracking based on his PhD.

Read moreJonathan Baggs FREng

Jon Baggs is one of the most experienced nuclear safety consultants in the country, leading on first of type, multi-million-pound safety cases, including the intermediate level waste store at Hunterston A power station.

Read moreProfessor Wyn Meredith FREng FLSW

Professor Wyn Meredith has made outstanding contributions to industrial engagement in UK semiconductor device research over a 30-year career.

Read moreProfessor Richard Miller FREng

As Founding President of Olin College of Engineering in the US in 1999, Professor Richard Miller is credited with developing a higher education institution renowned for its excellence in engineering education that has had profound transformational global impact.

Read moreProfessor Ruth Cameron FREng

Professor Ruth Cameron has an outstanding 30-year track record of pioneering world-class interdisciplinary research. Her transformative work has impacted the fields of medical materials, pharmaceutical engineering, and polymer engineering.

Read moreProfessor Michael Clinch FREng

Professor Mike Clinch is an influential industrial leader with over 25 years of experience in advanced materials and high-value manufacturing organisations.

Read moreProfessor Bikash Pal FREng

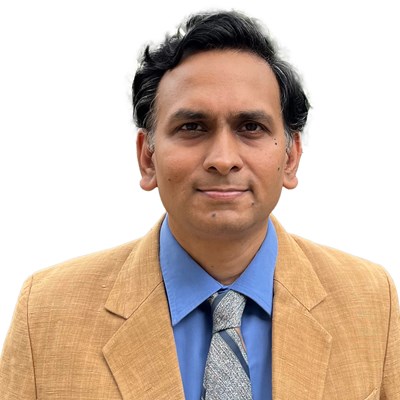

Professor Bikash Pal is internationally known for innovations and engineering achievements contributing to the stability and control of power networks with renewable generation.

Read moreProfessor Richard Dawson FREng

Professor Richard Dawson is an outstanding engineer, internationally recognised for his work on climate change adaptation of cities and infrastructure.

Read morePeter Dearman FREng

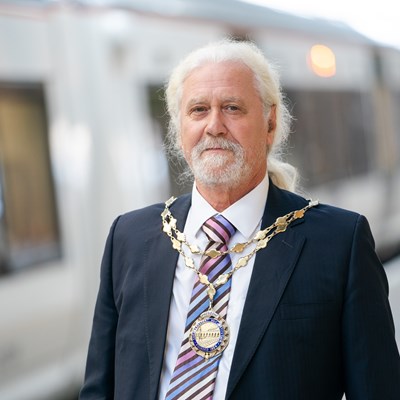

Peter Dearman is renowned for his leadership of railway electrification and system safety for the UK rail network and is regarded by many peers as the leading rail electrical and mechanical engineer of his generation.

Read moreProfessor Viola Vogel FREng

Professor Viola Vogel discovered the first high-resolution structural mechanisms about how nature exploits proteins as force-regulated nanoscale mechano-chemical switches, validated them in cell culture, and now translates them towards medical applications.

Read moreDr Robert Deaves FREng FLSW

Dr Rob Deaves has made outstanding contributions to robotics research, development and academia-industry collaboration.

Read moreJohn Downes FREng

John Downes has shown exceptional leadership in the power generation sector through a period of immense change. He was responsible as design authority across a portfolio of major Thermal and Renewable generation projects including Offshore and Onshore Wind, CCGT and Energy from Waste technologies.

Read moreDr Marc Harper FREng

Dr Marc Harper is the leader of the wireless development team for Surface and Microsoft, where he oversees the design and implementation of wireless technologies for various products and devices.

Read moreDr Rosemary Francis FREng

Dr Rosemary Francis is a technologist and entrepreneur who built and sold a world-class software business, where she invented and took to market unique products that solved important problems in high-performance computing.

Read moreProfessor Robert Killey FREng

Professor Robert Killey has made pioneering contributions to optical fibre communications technology, in the areas of fibre nonlinearity and the applications of digital signal processing in optical transceivers.

Read moreProfessor Michael Fitzpatrick FREng

Professor Michael Fitzpatrick is an internationally respected materials engineer renowned for his contribution to the development and application of experimental stress analysis.

Read moreProfessor Sean Gong

Professor Sean Gong is a computer vision and machine learning scientist. He pioneered person re-identification and video behaviour analysis for law enforcement.

Read moreProfessor Alex Frangi FREng

Professor Alex Frangi pioneered computational medicine with internationally leading contributions in fundamental and translational computational medical imaging and image-based computational medicine.

Read moreProfessor Stepan Lucyszyn FREng

Professor Stepan Lucyszyn is world renowned for his pioneering work in microwave engineering.

Read moreProfessor Ashwani Gupta FREng

Professor Ashwani Gupta is a leading international authority on swirl flows and volume distributed combustion.

Read moreProfessor David Greenwood FREng

Professor David Greenwood is currently working on delivery mechanisms and funding proposals to provide the next-generation skills needed by the future automotive industry.

Read moreAir Vice-Marshal Simon Ellard CB FREng

Air Vice-Marshal Simon Ellard has a distinguished career as a senior engineering leader in the Royal Air Force (RAF) and internationally in many project director roles, spanning over 30 years.

Read moreDr Caroline Hazlewood FREng

Dr Caroline Hazlewood leads the highly successful Flood and Water Management Group at HR Wallingford and oversees the flood modelling software distribution business in Italy and Malaysia.

Read moreDr Simon Harrison FREng

Dr Simon Harrison is a leading voice in public policy around engineering’s implications in energy transition and decarbonisation.

Read moreProfessor Graham Hutchings CBE FREng FRS

Professor Graham Hutchings is distinguished for his work pioneering the use of gold catalysts. He was the first to predict and subsequently demonstrate that gold would be a highly effective catalyst for acetylene hydrochlorination to produce vinyl chloride monomer (VCM), which is now commercialised extensively in Asia.

Read moreDame Angela McLean DBE HonFREng FRS

Professor Dame Angela McLean DBE FRS is the Government Chief Scientific Adviser having taken up the role in April 2023. She is also Head of the Government Science and Engineering Profession.

Read moreIan Funnell FREng

Ian Funnell is Chair of the UK’s National Nuclear Laboratory, Chair of the NG Bailey Group, Chair of the Energy Futures Laboratory at Imperial College London, and advisor to the Chair of Hitachi Europe.

Read moreProfessor Felix Schmid FREng

Professor Felix Schmid is highly respected for championing systems engineering in railway projects and operations and for creating and developing the first advanced education programme for the railway industry.

Read moreProfessor Wenfei Fan FREng FRS FRSE

Professor Wenfei Fan is distinguished for developing new data management theories and applying them to practice through commercial systems and products.

Read moreDr Andrew Mackintosh FREng

Dr Andrew Mackintosh has a distinguished career leading and supporting organisations that are at the forefront of scaling up and commercialising new technology.

Read moreProfessor Julian J Bommer FREng

Professor Julian Bommer is a civil engineer who works at the interface between Earth sciences and geotechnical and structural engineering, with a specific focus on mitigation of the risks posed by natural and induced earthquakes.

Read moreProfessor Ahmed Kovacevic FREng

Professor Ahmed Kovacevic is internationally renowned for pioneering methods and tools to design rotary positive displacement machines. His sustained and distinguished career has allowed him to make an outstanding contribution to the compressor industry.

Read moreProfessor Paul Needham FREng

Professor Paul Needham is recognised internationally for his outstanding contributions to solving Engineering problems in aerospace design and manufacture across multiple aircraft platforms.

Read moreProfessor Bill O'Neill FREng

Professor Bill O’Neill is widely acknowledged as a leading expert in the field of high-power lasers and their use in materials processing. He founded the Centre for Industrial Photonics at Cambridge University, focusing on delivering new laser-based manufacturing solutions to industry.

Read moreProfessor Timothy O'Farrell FREng

In wireless communications, Professor Timothy O’Farrell has made significant contributions in waveform and energy-efficiency design for radio access networks (RANs).

Read moreProfessor Jim Al-Khalili CBE HonFREng FRS

Professor Jim Al-Khalili is a well-known author, broadcaster and science communicator. He is a past president of the British Science Association and a recipient of the Royal Society’s Michael Faraday and Wilkins-Bernal-Medawar medals, the Institute of Physics Kelvin medal and the Stephen Hawking Medal for Science Communication.

Read moreGwen Parry-Jones OBE FREng

A chartered physicist, Gwen Parry-Jones OBE FREng has invested her working life in delivering large engineering projects across the full nuclear enterprise.

Read moreProfessor John Dear FREng

Professor John Dear is an outstanding international leader in developing and applying innovative speckle strain mapping techniques to high-speed impact of composite structures for aircraft, structural health monitoring of critical engineering components for power-stations and blast resistance of laminated glass structures for landmark buildings.

Read moreProfessor Keith Worden FREng

Professor Keith Worden is a world-leading authority in structural dynamics, notably in the areas of nonlinear dynamics and structural health monitoring.

Read moreProfessor Harish Bhaskaran FREng

Professor Harish Bhaskaran is distinguished for his research achievements in engineering nanoscale devices including breakthrough photonic or neuromorphic computing and displays.

Read moreDavid Quarton FREng

David Quarton is a leading light in wind energy engineering. He led a team of around 100 engineers who designed 20 multi-megawatt turbines for customers in Europe, the US, China, and Korea.

David Riordan FREng

David Riordan is an exceptional engineer who has developed an international reputation in the field of aerospace engine nacelle design, analysis and testing.

Read moreProfessor Catriona Savage FREng

Professor Catriona Savage has risen quickly within the naval architecture profession, making an impact in industry, academia and the professional institutions.

Read moreDr Chris Robinson FREng

Dr Chris Robinson is recognised internationally as an expert in turbomachinery and for having built up PCA Engineers, a UK-based SME, into one of the world’s leading, independent consultancy businesses in gas turbine and turbomachinery design.

Read moreProfessor Malcolm Macdonald FREng FRSE

Professor Malcolm Macdonald is distinguished through his role in shaping the future of the space sector, both nationally and internationally.

Read moreProfessor Ashwin Seshia FREng

Professor Ashwin Seshia has made significant contributions to the fields of microelectromechanical systems (MEMS) and sensor systems.

Read moreDr Jon-Paul Sherlock FREng

Dr Jon-Paul Sherlock is a highly influential chemical engineer, differentiated throughout his career in pharmaceuticals by his passion for technical innovation.

Read moreProfessor Iain Todd FREng

Professor Iain Todd is an international authority in the field of powder metallurgy and additive manufacture of metals and alloys. His work focuses on enhancing the manufacturing rate while simultaneously improving component quality and structural integrity.

Read moreDesmond Balmforth FREng

Des Balmforth is a chartered mechanical engineer with significant multidiscipline experience across manufacturing, engineering, project management and procurement.

Read moreProfessor Ashutosh Tiwari FREng

Professor Ashutosh Tiwari is internationally renowned for research in digital manufacturing and works in partnership with industry to develop new techniques and solutions for digitalisation, instrumentation, in-process monitoring and real-time simulation of skill-intensive manufacturing processes, such as wing manufacture and engine assembly.

Read moreJack Stockdale OBE FREng

Jack Stockdale OBE is an outstanding software engineer and technical leader who is recognised for the development of novel machine learning, artificial intelligence and cybersecurity methods and systems that are at the core of widely used commercial products for Darktrace, blinkx and Autonomy.

Read moreDr Ken Sutherland FREng FRSE

Dr Ken Sutherland is a leading engineering figure at the interface between medicine, engineering and the life sciences in Scotland and the UK. His influence in this sector has translated into global medical products that bring benefit to clinicians, patients, researchers and the medical industry.

Read moreProfessor Barbara Shollock FREng

Professor Barbara Shollock is a leading advocate for engineering through a range of activities, most recently as founding Head of the relaunched Department of Engineering at King’s College London.

Mark Wild OBE FREng

Mark Wild has more than 35 years of experience leading complex and critical infrastructure. Mark took up the role of CEO for Scotia Gas Networks, one of the UK’s largest gas distribution networks, in August 2022.

Read moreProfessor Daryl Williams FREng

Professor Daryl Williams is an internationally recognised expert in particle engineering and inventor of novel powder surface characterisation instruments, globally commercialised by his company Surface Measurement Systems.

Read moreProfessor Nadine Aubry FREng

Professor Nadine Aubry has made outstanding contributions to fluid mechanics, particularly turbulence, microfluidics and reduced order modelling and leadership in the global engineering community.

Read moreDavid Peattie FREng

David Peattie is a highly regarded international engineering leader in the energy sector. Since 2017, he has been Group CEO of the UK’s Nuclear Decommissioning Authority.

Read moreDr Andy Wright FREng

Dr Andy Wright is recognised for his strategic leadership of research and technology and its commercialisation for BAE Systems UK, and for his broader leadership of the industrial, government and academic nexus for defence research and development.

Read moreDame Kate Bingham DBE HonFREng

Dame Kate Bingham has spent 30 years building and investing in biotech companies as Managing Partner at SV Health Investors, one of the longest tenured biotechnology investors globally.

Read moreLord David Willetts PC HonFREng FRS FMedSci

The Rt Hon. Lord Willetts is the President of the Resolution Foundation. He served as the Member of Parliament for Havant (1992 to 2015), as Minister for Universities and Science (2010 to 2014), and previously worked at HM Treasury and the No. 10 Policy Unit.

Read moreChristopher Young FREng

As Group Chief Engineer of Rolls-Royce Group, Chris Young is the senior functional leader for engineering across the whole company and is responsible for ensuring the safety and quality of all products and services delivered.

Read moreDr Pavel Cheben FREng

Dr Pavel Cheben is a global leader in photonics, integrated optics science and engineering. His groundbreaking contributions in silicon photonics have fuelled fundamental advances across multiple technologies, enhancing both short- and long-range communication links, biomolecular sensing, and on-chip spectrometry.

Read moreProfessor Bashar Nuseibeh FREng

Professor Bashar Nuseibeh has led fundamental research and development of many award-winning and high-impact software requirements technologies and their practical applications for the assurance of evolving and adaptive mission-critical systems.

Read moreDr Dennis Ganendra FREng

Dr Dennis Ganendra, as an outstanding civil engineer, has grown his business to become one of the largest, award-winning multidisciplinary engineering consultancies in Southeast Asia.

Read moreProfessor Vikram Deshpande FREng FRS

Professor Vikram Deshpande has made seminal contributions to the mechanics of engineering materials.

Read moreProfessor Tim Abram FREng

Professor Tim Abram is internationally renowned in the field of nuclear engineering with specific expertise in nuclear reactor and fuel design.

Read moreProfessor Wolfgang Marquardt FREng

Professor Wolfgang Marquardt is a pre-eminent member of the world’s process systems engineering community, having made seminal contributions across the entire spectrum.

Read moreBaroness Martha Lane Fox CBE HonFREng FMedSci

Co-Founder of Lastminute.com, Baroness Lane-Fox of Soho was influential in starting the UK’s dot com boom in the late 1990s. Today she is a businesswoman, philanthropist and public servant.

Read moreProfessor Joby Boxall FREng

Professor Joby Boxall is a leading international authority on urban water engineering and is recognised for his research on drinking water distribution systems infrastructure.

Read moreProfessor Georgios Giannakis FREng

Professor Georgios B. Giannakis has made pivotal and pioneering contributions to statistical signal processing, telecommunications, sensor networks, data science, graph learning, patents influencing wireless standards, and mentoring of young researchers.

Read moreDr Joshua Macabuag FREng

Dr Josh Macabuag has provided technical advances in catastrophe risk modelling, quantifying disaster risk for renewable energy, via his own company, Renew-Risk and for developing countries, via the World Bank.

Read more